How to make a Table Runner into a Blind

This blind started out as a table runner.

I gave it to my sister Kim when I was visiting her and I thought I was done with it. She loved it and wanted it to be part a window cover.

It gets very hot inside the room during the summer so something to block the sun. This is the first time I have covered a window with this shape but I am up for a challenge. After figuring out the little problem with her wonderful Featherweight sewing machine and visiting the local quilt shore in her town Denton Texas I set to work. I than had to figure out how it was to be hung up to block the late afternoon heat.

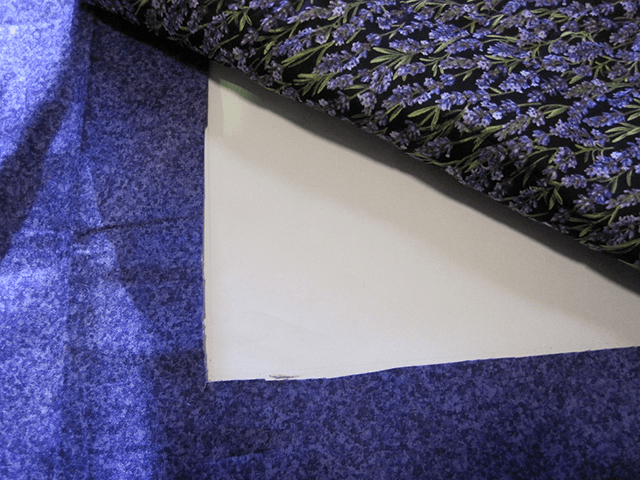

The quilt store turned out to be Minding My P’s and Q’s quilt shop a fun store that filled all of our needs such as the white fabric which is a blackout fabric. They also had this purple that went right along with the table runner. Kim likes purple and green more on the earthy side.

I took the measurements and had to figure out the how it would look with it twice as big at the bottom as the top. The hanging part had to be long enough to go around the pole and hang down past the window with a pole or something to fit in the bottom and keep it out the full length of 83”. The top is 42” and it has to be 40” tall after it is all hemmed up.

I came up with this unusual shape. Something like a very large flat bell.

In the middle of this project I kept hearing the clicking of the needle when it went through the fabric. I thought it was a dull needle. I changed the needle out and it didn’t even go through to catch the bobbin thread. Taking the bobbin out I could not see what the needle was catching on. I only had a day and a half to get this blind done. I called Denton Sewing Center a great shop that I found when I was there in 2015. Bob one of the repairmen in this store got the Featherweight up and running by the next day. It turned out to be a slight timing issue and the old needle must have been gently bent so it would work. I would highly recommend Denton Sewing Center if you live in Denton Texas. If you want to find out more about the reason why I picked this sewing machine repair store please see my blog about the importance of having a great repair place for your machines.

As you are looking at the picture you can see the big white space on the right side of it. I didn’t have enough fabric to cover it all so I decided to use the fabric underneath the table runner. Cutting the fabric carefully out of the middle of the Table Runner space then sewed it onto the white area to cover the that space. It covered the area perfectly.

Here is a little secret, I used double sided tape to hold the curved part of this blind up against the wall. If I hadn’t done this you would see the back flipped to the front. One of those keep it simple ideas. Taking the height and measuring again I made the blind my 40” with a pocket to slide the rod into on the bottom to get my finish product. Kim really likes how it came out and that is the best part of doing something custom like this.